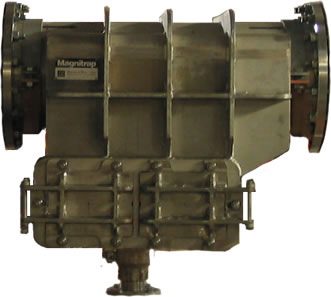

The BemaTec Magnitrap is a magnetic contaminant separator offering effective protection for paper machinery and stock preparation equipment.

Thanks to its specific design, this separator removes both magnetic materials and heavy non-magnetic materials.

FEATURES AND BENEFITS

Easy to install

No pressure loss

Withstands operating pressures up to 10 bars

Maintenance free

No water connection for flushing

10-year warranty

No spare parts

No energy consumption

CONSTRUCTION

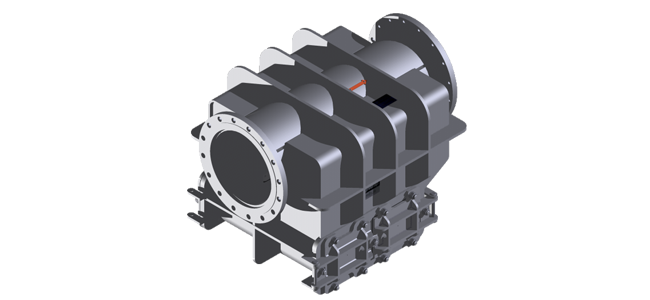

The main body is made of stainless steel. The inner section comprises an inlet pipe, a baffle and an outlet. A three-inch pipe plug is provided on the underside for drainage prior to cleaning. Hinged doors provide easy access for periodic cleaning of the housing and the magnetic plates.

Its simple, robust construction ensures trouble-free continuous operation. The separator is rated for a pressure of 10 bars and can be used in high-performance installations.

Wear is minimal, and since there are no moving parts there is no need for maintenance. The magnetic separator is designed to withstand the high throughputs common to paper-making today.

OPERATION

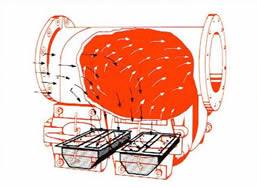

The stock enters the separator horizontally and is immediately channeled downwards against the magnetic plates positioned at right angles in the center of the magnetic field.

The flow velocity is approx. 25% slower in the space above the magnetic plates than in the pipe (depending on the flange diameters).

The flow direction is reversed simultaneously and the stock flows upwards towards the horizontal outlet. A baffle prevents the stock from flowing directly from the inlet to the outlet.

The reversal in flow direction combined with the sudden reduction in flow velocity ensures that heavy non-magnetic materials are attracted to and trapped within the space surrounding the magnetic surface with optimal efficiency.

The accumulated materials must be removed regularly at intervals depending on the level of contamination.

MAGNETS

Powerful permanent ceramic magnets are fixed inside watertight stainless steel boxes. There is no direct contact between stock and the magnets.

Since the magnets are not electro-magnets, no energy is consumed and there is no need for human intervention.

THE SUCCESS OF MAGNETIC SEPARATORS

BemaTec magnetic separators are operating in hundreds of the most advanced mills in the pulp and paper industry.

Our customers recognize the efficiency and reliability of our separators, and recommend them to their peers.

Maximum operating pressure: 10 bars

Three different sizes are available:

• up to 50 t/day

• 50 to 100 t/day

• 100 to 200 t/day

Larger throughputs may be treated by using several units installed in parallel.